Society of Petroleum Engineers. Abu Dhabi, UAE, November 2016. Increased Oil Recovery by Application of Plasma Pulse Treatment

A. F. Pashchenko, Institute of Control Sciences of Russian Academy of Sciences

N. P. Ageev, Novas Energy Services Ltd.

Abstract

Advanced technology of increased hydrocarbons recovery – Plasma Pulse Treatment (PPT) is presented. The explanation of physical impact on the reservoir is given. Examples of laboratory studies and field-testing observed.

The physical bases of the PPT are periodic pulses of equal strength, spaced with equal time intervals by discharge current passing through a metal conductor. Shock wave, formed by the explosion of conductor, is propagating radially with supersonic speed, gets out through the perforation holes and provides an elastic compressive and tensile impact on the media. Low frequency waves, propagating deep into reservoir, contribute to the development and formation of new cracks, as well as the transformation of sub-capillary pores into capillary, causing the liquid moves from stagnant zones and channels to the zone of active drainage.

The paper presents the description of the physics of a process as well as some calculations and estimates of observed technical parameters. Some estimates and calculations, given in the paper, are based on the principles of nonlinear physics and fluid dynamics.

Laboratory studies confirmed substantial changes after PPT application both in oil samples (resulting in viscosity reduction) and core samples (increase of permeability).

Microseismic studies, carried out on the field, registered the propagation of waves, created by PPT, on a distance of over 1.3 kilometers away from a treated well.

Number of well studies both production and injection ones is presented, showing the long lasting effect of treatment. The overall analysis of over 300 treated wells is given, proving the high efficiency of Plasma pulse technology. Technology, presented and described in the paper, allows increasing the productivity of hydrocarbons wells and involving the reserves of residual and unrecoverable oil into production.

Introduction

The geological oil reserves of all known deposits in the world reach more than 500 billion tons, with more than 300 billion tons belong to the category of hard-to-recover or unrecoverable with use of the modern industrially developed recovery methods (Tarnovsky E.I., 2009). At the same time, extraction of the residual reserves, even in the range of 10-15% of oil (30-45 billion tons) is equivalent to about 10-15 trillion US dollars (considering a price of 50-60 dollars/barrel) and represent a large reserve and an important target for all oil producing companies.

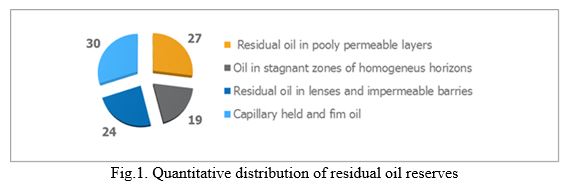

Residual oil reserves of undrainable formations and not covered with flooding streaks are fairly well studied and can be quantitatively distributed as follows:

- residual oil in poorly permeable layers and areas, not covered by the flooding - 27%;

- oil in stagnant areas of homogeneous layers - 19%;

- residual oil in lenses and at impermeable shields, not discovered with the wells - 24%;

- capillary held oil and oil films - 30%. (Fig. 1).

The problem of the residual oil development can only be solved with use of high technologies, relating by the common terminology to tertiary oil recovery methods. Combinations of physical-chemical processes can be used as those methods, application of which allows to "squeeze out" as much of the remaining oil in the reservoir as possible. These technologies are currently being developed intensively. Herewith the most important is to define the basic principles of the impact at the collector that will ensure the greatest efficiency (resource, economic, environmental) of hydrocarbons extraction process.

Almost all traditional EOR (enhanced oil recovery) methods represent an improvement of conventional recovery processes, and their theory is representing the development and generalization of the basic concepts of the theory of two-phase filtration of liquids and gas, based on the linear Darcy's law and on linear dependences. Undoubtedly, linear laws and linear relationships exist, but it is rather the exception than the rule.

At the same time, in the 50-s the last century, it was found that non-Newtonian fluid, including oil, at low velocities of filtration is not subject to linear Darcy law and is entirely dependent on the interaction of phases, indicating the nonlinearity of oil filtering. Therefore, the problem of extraction of residual reserves should be observed in terms of non-linear processes taking place in any productive deposit, regardless of what of its development stage.

Based on the background mentioned above, company Novas in collaboration with leading scientific institutes has proposed an original solution for the extraction of residual oil, consisting in the impact on the productive media with targeted wide-range periodic short pulses of equal strength, spaced with regular time intervals, through the operational intervals of producing or injection wells – Plasma Pulse Treatment (PPT).

Basic principles of Plasma Pulse Technology

A significant role in solving the problem of enhanced oil recovery should be paid to the elastic properties of the formation. The elastic properties of the reservoir are well known and are determined mainly by the depth of stratification; gravity and gravitational-capillary forces; porosity; permeability; temperature; viscosity of oil, water and the formation pressure. During the well operation, the elastic properties of the formation start to appear as a factor, reducing reservoir pressure, causing a reduction of cracks and, therefore, these forces contribute to residual oil saturation occurring in the stagnant zones, impermeable lenses and screens.

Gravitational forces create a permanent pressure gradient, numerically equal to the difference between the density of oil, gas and water.

Capillary or surface forces create at the boundary of the liquid phases the surface tension, which is determined by the wettability of rocks and micro-inhomogeneity of the porous medium, the pore size, pore channels, capillaries, micro capillaries.

Viscous forces – hydrodynamic resistance, which is proportional to the viscosity of the oil. This is fair to consider that factors such as oil viscosity, low permeability of layers and interlayers, and also carbonate content of reservoirs affect negatively at the rate of residual oil production.

Water - oil - gas and reservoir itself - it is a dynamic system, where all the phases interact with each other, penetrate into each other and influence each other.

In addition, in the productive deposits there are constantly natural non-damping free oscillations taking place, giving disequilibrium to reservoir, controlled by a stationary circular (angular) frequency, which is called sometimes the dominant frequency. In works on geomechanics and fluid dynamics it is mentioned, that each productive reservoir has its own dominant frequency, which depends on a micro-structural, viscoelastic and stratification resonances (Nikolaevsky V.N., 1996). The dominant frequency may play a key role in the stimulation of inflow to the oil wells, but it is almost impossible to identify it (in the literature one can find various parameters - from 5-20 Hz to 172 Hz or more), as, being a stationary circular frequency of free oscillations, it is constantly changing in time and space.

The physical basis of the Plasma Pulse Treatment are periodic pulses of equal strength, spaced with equal time intervals by discharge current passing through a calibrated metal conductor (wire), which after the explosion is converted into steam with a high density, temperature and pressure. Shock wave, formed by the explosion, is propagating radially with supersonic speed, gets out through the perforation holes and provides an elastic compressive and tensile impact on the media.

Wire explosion initiates the formation of the elastic waves of high amplitude (including shock waves), the compression phase of which is distributed at a higher speed than the tension phase. The main property of waves, whatever their nature is, is that in a waveform the energy transfer is carried out without the transfer of substance. In this case, the energy flow to the external environment is usually negligible and it can be neglected.

Due to periodic shock impacts in the area of the perforation holes, the sediments are detached from the walls of pore channels. Compression waves, reflected many times, transform into tension waves, which contribute to the development and formation of new cracks, as well as the transformation of sub-capillary pores into capillary. Pressure drops during pulse action alternately change in magnitude and direction, causing the liquid moves from stagnant zones and channels to the zone of active drainage.

Oscillations, generated in the reservoir, should be as much as possible corresponding to the frequency of natural oscillations of the rock matrix and the saturating fluids. These vibrations cause multiple effects, affecting the liquids and gases contained in the formation: they reduce the cohesive and adhesive contact, greatly reduce the expression of capillary forces, sticking between rock and fluid, tending to encourage the clustering of oil drops into the streams, making the flow easier for hydrocarbons in the porous medium.

Elastic waves promote the development of the oscillating forces in the formation, which leads to different accelerations of reservoir fluids (oil, water, gas) due to the difference in their densities. Surface friction develops between liquid phases, which promotes the release of heat, which, in turn, reduces their surface tension.

Creation of pressure differential contributes not only to purification of the pore channels of the formation, but also to destruction of its skeleton. Pressure increase leads to expansion of existing cracks in the reservoir and the formation of new ones. The decline of pressure is accompanied by closing them. Repeated deformations contribute to fatigue failure of rocks and chipping off the reservoir fragments with low permeability. Changing the speed and direction of the fluid motion in the well supply area at the pressure change on the walls of the producing formation allows using radial and tangential forces, to expose the formation rock with the effects of compressive stress, tensile, bending and shear, i.e. shake, and break out its dye particles. Cut off the solid particles in the liquid flow are abrasive and can serve the functions of a proppant. Oil as any structured media, has the property of thixotropy, which consists in the fact that by shaking the medium, there is a sharp decrease in its viscosity due to the destruction of the structural framework.

Impact by the shock waves on the reservoir

Since the basis of plasma pulse treatment on the oil-bearing formation is the generation of compression-tension waves, caused by the explosion of the metal conductor and the gas bubble pulsation, of particular importance is the determination of the explosion energy, temperature and velocity of the pressure pulses formation.

The design of the PPT tool “Plasma Streamer-102” provides a metal wire as locking the electrodes conductor, with a diameter of 0.45 mm and a length of 30 mm. Voltage U of the capacitors, fully charged at the time preceding the discharge, is 3000 V in operation mode, the capacity C of the parallel connected capacitors’ battery - 250 μF. The discharge time, defined by the characteristics of the particular capacitors, - 55 microseconds. The energy of the discharge in this case, basing on the above conditions, is equal to 1125 J.

Design of PPT generator is shown in Fig.2.

With the explosion of the wire in the fluid, provided that the energy stored in the capacitors is greater than the energy of evaporation of the conductor, there is an instantaneous heating, arc discharge occurs, the wire is evaporated, and the pressure pulse develops.

Most of the total energy is released in the explosion of a wire within a discharge cycle in about 55 μs. Exploding wire expands, forming a spark channel. With further expansion of the spark channel a gas bubble is formed, expansion of which lasts until the maximum radius at which all the kinetic energy is transferred to the water medium, creating a shock wave. The increased potential energy of the water is again reported to the bubble, causing its compression to a minimum. This cycle is repeated until the bubble energy decreases due to the emission of acoustic shock waves at consecutive minima, and also due to condensation and viscous losses in the water. There may be 2-3, less often 3-4 of such cycles, before the energy is completely dissipated. As a result of a series of repeated during the PPT discharges at regular time intervals, series of compression-tension waves is created in the medium, contributing to increase the inflow of fluid to the well.

Assuming we have a copper wire as an explodable conductor, knowing the characteristics of the material (volume, density, molar mass, specific heat of melting and vaporization), we are able to calculate the energy required for conversion of conductor into steam (sublimation energy). This energy is equal to 212.65 J. Herewith the evaporation temperature of copper will be achieved Tvap = 2840.15 K.

Based on several studies, particularly (Buntzen R., 1965), we can assume that the energy of the gas bubble formation takes approximately 30% of the total energy of the explosion. Considering that the explosion of the wire takes place in a very short period of time, almost immediately, it can be assumed the original volume of gas is equal to the volume of the blasting wire and apply the equation of Kinetic Molecular Theory (KMT) for an ideal gas to it, assuming the absence of heat exchange with the liquid. Then, the temperature to which the gas is heated up is determined from the expression

where T - the temperature, n - molecular concentration (N - total number of molecules of copper),

- the average kinetic energy of the molecules, M - molecular weight, ρ - density of material, R - the universal gas constant 8.31 J/mol·K. Since the expression (1) actually means the temperature, added to a substance already in the ideal gas state, then we must add the copper evaporation temperature to the obtained value. Then the maximum temperature, which a gas bubble from exploded copper conductor can reach, will be 36719 K. Instant heating of the metal to such a high temperature leads to the formation of the plasma, as there is thermal ionization of the particles. The discharge current stops with the formation of plasma, the plasma cloud starts to expand, transforming the acquired energy into the pulse pressure.

In consideration of (1) the pressure value at the moment of the wire’s explosion can be estimated by Clapeyron equation (Pashchenko A.F., Ageev P.G., 2015)

These arguments and estimates are fair for the initial time moment, until the gas occupies a volume equal to the initial volume of the copper conductor.

It should be noted that the numerical characteristics obtained in the real conditions might be somewhat lower due to factors such as the additional resistance of the discharge circuit, partial discharge of the capacitor during operation mode, etc. Nevertheless, the general order of these values shows that the explosion of a copper conductor forms a cloud of metallized gas with temperature, corresponding to the conditions of existence of low-temperature plasma, extremely high pressure pulse and ultrasonic propagation velocity of the particles.

Despite the high value of the overpressure, due to the short duration of exposure, it does not destroy the material of well’s column. This fact has been proven by number of CBL studies carried out by some oil companies before and after application of PPT. However, a sharp, heavy impact of the shock wave destroys fragile, having a relatively low strength, sediments. The next phase of the action is "shaking" the ruined sediment by pulsation of the explosion products. When the initial expansion of the gas bubble growing, pressure pushes fluid from the wellbore into the formation. Then, the hydrostatic pressure starts acting on the gas bubble, compressing it, and the fluid seeks from the formation into the wellbore, helping to remove sediments from perforation holes. Repeated many times during PPT pulsation with damped amplitudes can cause eventually a substantial increase of the fluid inflow to the well.

Alteration of shock wave with its propagation

The generalized formula of M.A. Sadovsky to calculate the overpressure from the explosion of any explosive in different gas mediums is of the form:

where ΔP - overpressure, U1 - the specific energy of an explosive, UT - the specific energy of TNT, P1 - the pressure of the unperturbed medium, P0 - normal air pressure, R - the distance from the explosion, m - mass of the explosive charge.

The shock wave in the water can be considered, based on the same assumptions that form the basis for the study of air shock waves. We can assume that the water (or gas-liquid medium) is a gas, but it is extremely highly compressed by molecular forces, i.e., with a very strong attraction of the molecules to each other. This attraction is compressing water so much, as if it was compressed by external pressure, about 10,000 times exceeding the normal atmospheric air pressure. Since different external loads without substantial gas phase can hardly change the density of water, it is usually assumed to be incompressible. But with the explosion, some compression of it still occurs there and it is accompanied by a sufficiently high pressure occurring in water behind the front of the water shock wave. Thus, assuming that P1 for the water is 10,000 times greater than for air, the formula (3) can be written as (Orlenko L.P., 2006)

We proceed from the fact that the power density of TNT is 4184 kJ/kg, and the energy of the explosion of the copper conductor in this case amounts to about 6645 kJ/kg (282.8 J. referred to 4.25587 × 10-5 kg). As example, we take one of the standard well casing with an outside/inside diameter of 168/150 mm. Then, at a distance equal to half the diameter of the production casing of 75 mm,

Simulation of the overpressure decay process with changing distance from the center of the explosion confirmed the well-known theoretical conclusions that pulse pressure is rapidly decreasing in time with exponential law.

Laboratory studies on core and fluid samples

For the purpose of determining the influence of Plasma-Pulse Treatment on the crude oil properties and also to justify the possibility of PPT application for extraction of heavy and high-viscosity oil, the Department of Development and Operation of Oil & Gas fields at the Saint Petersburg Mining University, Russia, has performed laboratory studies of properties of high-viscosity oils from Tatarstan (Romashkinskoye field, ρ=0.874 g/cm3, μ=40,9 mPa∙s) and Komi area (terrigenous layer of the Usinskoye field, ρ=0.94-0.97 g/cm3, μ=710 mPa∙s; Ac-23%, P-12%). As viscosity of these oils depends to a large measure on the layer temperature, the measurements were carried out at +10°C, +20ºC, +30ºC, +50ºC and +70°C.

The research aim was studying a possibility of lowering the oil viscosity anomaly by a plasma-pulse impact on the producing formation. The experimental analysis of the rheological and filtration properties of the high-viscosity oils were conducted using the advanced Coretest System Corporation installations: the Hezzog–HVZ 472 automatic viscosimeter; the Rheotest 4.1 rotary viscosimeter; filtration and capillary pressure measurement installations, and the Vertex 70 infrared interferometer spectrometer.

Adjustment of the high-viscosity oil thixotropic properties during deformation at a constant rate of shear results in reduction of the effective viscosity with time. Thixotropy is a reversible process, and after removal of load, the destructed coagulation structure of the liquid restores. Duration of the structure restoration after removal of loads presents a practical interest.

The hysteresis loop area corresponds to the energy related to the volume of the sample subjected to shear loading, and determines the value of energy required for thixotropic structure destruction.

Application of plasma-pulse technology at the high-viscosity oil fields facilitates decay of the thixotropic structure of high-viscosity oils ensuring a long-lasting effect. According to the measurements, restoration of the Romashkinskoye oil structure takes 110 days, Usinsk oil – 195 days. The hysteresis loop area has decreased by 48% (Fig. 4).

The obtained results showed viscosity reduction following PPT by 10-20% within the temperature range of +20 to +40ºC. Evidently, the elastic wave impact causes changes in the intermolecular interaction structure that determines the thixotropic properties of the stratum fluid. The repeated measurements of the oil samples previously subjected to PPT performed in 10, 60, 100 and 200 days showed insignificant change of viscosity (Fig.5). In this connection, it can be assumed that the impact effect is long lasting.

See Table 1 for the results of the rheological measurement of the high-viscosity oils at the Usinskoye field after PPT (pulse number 10 to 40), they reflect a reduction of oil viscosity by 30%, and manifestation of the thixotropic properties up to 40%, depending on the viscosity of the treated oil.

Plasma-pulse impact on the oil asphaltenes dispersion was studied by the method of infrared photocolorimetry.

The spectral analysis of the Usinsk oil before and after PPT was carried out using the Vertex 70 infrared interferometer spectrometer, operating in a spectral range of 7500 to 370 1/cm. It was found that the optical density, as well as the oil optical transmission at the frequency of 1640 1/cm decreases. That occurs as a result of nucleus number increase and growth of the asphaltene particles free surface, which is possible only under condition of asphaltene dispersion.

The filtration studies were conducted on core samples before and after PPT using the FDES-645 installation. After PPT treatment of the Usinskoye field oil, the pressure gradient drops and oil mobility increases during filtration. The effect enhances with increase of the number of pulses implied for treatment of the producing formation model. The penetration tests of the core containing oil from the Usinskoye field after PPT by 40 pulses at a temperature of +30°C have shown an increase of oil mobility by 2.2-2.7 times and by 2.5-2.9 times at a temperature of +50ºC (Fig. 5).

Measurement of the capillary pressure was performed on samples of a water-saturated core using the TGC-764 installation (CaCl2 water solution of 1.01 g/cm³ density). After PPT, the capillary pressure increased by 1.5-2.0 times with core saturation below 40%. Such results reflect an increase of the filtration resistance related to the water phase. The obtained effect is determined by the process of formation water-repellency treatment, due in particular to the change of wettability of the core porous medium under PPT influence.

Microseismic monitoring research

In order to confirm the declared capabilities of PTT technology and get a tool for improving the methods of wells and reservoirs treatment, in 2015 pilot projects for passive microseismic monitoring over an area of 40,000 m² were held in two of the 4 degasification wells drilled in coal-bed methane layer. The distances between the wells were as follows: between A-1 and A-2 - 200 m, and between the wells A-1 and A-3, and also between A-2 and A-4 - 400 meters respectively. All wells were treated with plasma-pulse technology by specially chosen method to increase permeability, and hence create the conditions for the desorption of methane both from adsorbed surfaces, and from blocked cells (vacancies) in the crystal cell of the coal.

Choice of passive microseismic monitoring method for the research of the process and the results of PPT is associated with the fact that it does not require powerful sources of probing signals and uses constantly existing weak seismic fields of artificial or natural origin.

Since the seismic emission occurs in the geological environment due to the relaxation of elastic stresses caused by spontaneous deformations of the medium, often associated with the violation of continuity, physical fundamentals of passive microseismic monitoring technology are quite corresponding to effects (compressive and tensile stresses) initiated by Plasma-Pulse oscillations source.

Thus, the aim of the research was to determine the areas of microseismic activity in the course of the PPT application at different times in four wells, located at a distance of 200 and 400 meters from each other respectively. The coal seams themselves are presented by multi-layer sand-clay rocks with numerous coal seams and coal streaks. The area, where the treatment was applied, is an almost perfect monocline with the 9 -12 degrees angle of incidence to the southeast. The reference point in the wells have difference vertically up of 80 meters.

Recording of microseismic emission was carried out with the use of Areal Observing System - seismic antenna, based on 28 three-channel seismic stations SCOUT, which were installed in the projection of the horizontal sections of the wellbore to the surface. The total number of observation points of seismic antennas thus equals to 84, and the intervals between them was 20 to 30 meters. Aperture of a seismic antenna is 800 meters from north to south and 600 meters east to west. Frequency digitizing of a signal was 1 kHz (sampling period of 1 ms).

During the observation period from March, 23 to May, 04 2015 obtained more than 232 GB of data. The entire data was processed with the Technology of Inverse Problems, developed by a company TINP Ltd., Moscow, Russia. As a result, microseismic emission sources distribution map was obtained, considering the value of the reliability of emphasized sources of seismic events and their basic parameters determined: the coordinates in space, event time, frequency characteristics, the average velocity of propagation of seismic waves from the seismic source to the antenna.

In the A-1 well, situated in the upper part of the slope, 703 plasma pulses were held. The antenna has recorded the signals of microseismic activity from the artificial emitting source, which in the spectral-timing diagram were ranged from 4 to 35 Hz. This led to the conclusion that the identified periodic broadband signals of equal power, spaced at equal time intervals from the source of PPT just fall into the range of the fundamental (dominant) frequencies, initiating shear waves.

As a result of the interpretation, maps of recorded microseismic events and energy of microseismic emission density were compiled in projections to the surface. The total number of events corresponds to the number of pulses. The energy of methane emissions from coal and the creation of microfracks was 3004 kJ. The energy of the maximum shear stress was 1950 kJ. The energy of the compression 42.88 kJ, separation energy 35.83 kJ.

The map is built in the projection onto the horizontal plane (X - West-East; Y - North-South). The color indicates the density of the stored energy of microseismic events. The coordinate axes in meters, the values on the axes indicate distance in relation to wellhead A-1 (white dot).

The highest energy density of microseismic events observed under seismic antenna near the bottomhole of A-1 well. Area of microseismic activity has elliptical shape with a primary direction of distribution to the south-west azimuth of 225 degrees. Approximate linear dimensions of the microseismic activity area is 1,500 meters from north to south and 1,250 meters in the direction from west to east.

Equally, interesting results were obtained during microseismic monitoring of PPT at A- 3 well, which differ in the direction of increasing depth from well A-1 on more than 100 m with respect to reference points. In this well 1180 of periodic broadband pulses were initiated.

The energy of methane emissions from coal was 2215 kJ. Maximum shear stress energy - 1446 kJ. The energy of compression was 19.1 kJ, separation energy 18.16 kJ. Approximate linear dimensions of the microseismic activity area were around 1350 meters in the direction from north to south and 1,000 meters in the direction from west to east.

According to the analysis, during the observation period, the process of volume reduction prevailed over the process of the volume increasing and the process of closing of fracks respectively prevailed over the process of their opening. In other words, the lighter phase (gas) was transmitting into the free state from the pores, fracks and capillaries, causing a decrease of volume, with the simultaneous opening of closed pores and fracks and the development of microfracks in the solid rocks (coal). The clear evidence of that is the energy methane emissions from coal, 3004 kJ in the first and 2215 kJ in the second cases.

In general, it is possible with sufficient certainty to state that the observation of the kinematic and dynamic characteristics of the area of microseismic activity in the area of installation of the observation system indicates an increase of permeability of the layers at a considerable distance on the area, which is equal to more than 1 sq.km.

As a result, all 4 wells were linked by a system of filtration channels, and in the crater formed there was an active desorption of methane, some part of which turned into the free state. Borehole annulus pressure of the wells increased, and the bleed water was saturated with the gas, which took 10-12% of the pump volume.

Case studies on production and injection wells

The technology of plasma pulse treatment of productive oil reservoirs has been used successfully since 2007. To date, this technology processed more than 300 oil producing and injection wells in Russia, USA, Canada, Kazakhstan, China, Kuwait (Chellapan S.K. et al., 2015) and other countries, in most cases a positive technological effect was obtained.

Independent analysis of PPT Technology, conducted by a specialized engineering consulting company in 2015, contains the following conclusions:

-

87% of the production wells with carbonate reservoirs showed an increase in productivity. The average increase in productivity amounted to 99%;

-

71% of the wells in sandstone reservoirs, the development of which was initially carried out using hydraulic fracturing showed an increase in productivity. The average growth of productivity - 110%;

-

50% of the wells in sandstone reservoirs without fracturing showed an increase in productivity. The average increase in productivity was 24%.

In the treatment of the injection wells, the effectiveness of the PPT is exceeding more than 90%.

A number of studies during the pilot and industrial works demonstrate that in addition to enhanced permeability of the bottomhole and remote areas, the PPT has a positive effect on rheological and thixotropic properties of both the reservoir and oil, as it increases its mobility.

Representative results were achieved in the course of application of the PPT to the fields of LLC Polar Lights Company, Russia (a subsidiary of jointly Rosneft JSC and ConocoPhillips) confined to porous and fractured-cavernous types of limestone. As for technical characteristics of reservoir: oil density – 0.845-0.874 g/cm3; viscosity – 1.52-2.4 MPa*c; permeability of the strata – 0.009-41 D; porosity – 6.6-11.3%.

After the application of the PPT to a well on Ardalinskoye oil field, the oil production rate enhanced on the average by 23.7 tons/day, whereas the average increase in the fluid production rate was 22.8 m3/day. It is noteworthy that the water cut level decreased from 86% to 80% within the 3 month observation period. The well productivity index Pi increased from 2.87 to 3.11. (Fig. 9)

On Zapadno-Sikhoreyskoye oil field an open hole production well before the treatment worked with the following parameters: fluid (Qf) – 105 m3/day; oil (Qo) – 85 tons/day; water cut – 6.5%.

After the well treatment with the application of the PPT, the study of the well inflow profile (PLT) was carried out; it showed improvement in the productive characteristics of the formation. Fig. 10 presents the well parameters before and after the PPT.

The fluid (Qf) and oil (Qo) production rate doubled. The water cut increased by 3.5%. It should be noted also that the increase in bottomhole pressure after the Plasma-Pulse Treatment from 108 to 179 atm demonstrates significant additional potential of the well.

A cased-hole well with the following technological parameters was selected for the treatment on Dyusushevskoye field:

-

fluid production rate before treatment – 14 m3/day;

-

oil production rate – 1.8 tons/day;

-

water cut – 85%;

-

dynamic level (Hdyn) – 2.250 m.

The modeling calculations provided a basis for assuming that even if the water cut level remains at 85% (the water inflow profile was not known), one can expect an increase in fluid production (Qf) - up to 30 m3 and in oil production - by 3.8 tons/day (Ndyn = 2000 m).

Compared to uncased borehole treated with 1 m impact intervals and the number of pulses not greater than 20 at a point, in the cased well, the decision was made to reduce impact intervals to 0.5 m and increase the number of pulses at each point in 2-3 times (the calculation is based on geological features of the reservoir).

The well operation parameters after the application of the PPT in the predetermined mode:

-

average daily fluid production rate increased to 43.6 m3/day;

-

average daily oil production rate grew up to 11 tons;

- water cut decreased to 70.7 %. (Fig. 11)

According to the test results, the dynamic level (Ndyn) stabilized at around 1453 km, which is 800 m higher than before the PPT application and which shows good additional potential of the well.

Multiple applications of Plasma-Pulse Treatment have been carried out on injector wells. Method of Plasma-Pulse Treatment allows not only to increase the injectivity capacity of wells, but also to redistribute the pumped in liquid by the unwashed interlayers, thus increasing the scope of flooding the field to the maximum values. Fig. 12 presents an example of such treatment on Muravlenkovskoe oil field with terrigenous collector. The target was to increase the relative injection capacity of a particular layer 2872.0 – 2879.4m MD from 8 to 30%. It is shown that the injection capacity of a current interlayer increased from 29,2 to 150 m³ per day and its share in total capacity of the well increased from 8 to 32%.

For all cases it can be noted that the bringing of all treated wells to stable production was significantly faster than after the repair works previously conducted on these wells. Usually, a smooth decrease in the water cut level and the bringing of the well to the prerepair mode were observed within 3 days or more, due to the extraction of the absorbed well-killing fluid and, as a consequence, the deterioration of reservoir properties. After the Plasma-Pulse Treatment, all wells were brought to former oil production and water cut level during the first two days.

Conclusions

Seismic and geophysical studies have confirmed the declared and calculated theoretically capabilities of Plasma-Pulse Treatment technology when applied to productive hydrocarbon reservoirs. Distribution of the generated low-frequency waves strongly depends on the geological properties of the formation, but may in general be effective at a distance of several kilometers.

When applying the Plasma-Pulse Treatment, the crater formed in which four wells were connected to each other and when changing the operating mode at one of the wells, the rest immediately reacted in the form of oscillations of dynamic fluid level, or in the form of annulus pressure increase.

The laboratory studies of core and oil samples proved that Plasma Pulse Treatment reflects on the properties of both crude oil, practically reducing its viscosity and increasing the mobility, and rocks, increasing permeability and filtration abilities. Perhaps, more significant is the confirmation of long-lasting effect after PPT application.

Features of Plasma Pulse Technology, revealed in the studies, were confirmed in practice. In particular, when working in the later stage operation wells, their productivity increases and water production reduces, the well increases its supply circuit. Positive reaction has been noticed from the wells, drilled at the same layer at a distance from 250 to 1,500 meters (Chellapan S.K. et al., 2015), depending on the geological structure of the reservoir.

PPT Technology allows enabling phase impact, including the unwashed interlayers into operation, removing the surface tension in the capillaries and freeing capillary-held oil and gas. When applying PPT the permeability is increasing and porosity due to the release of the light phase is reducing. The duration of the effect lasts from 6 months to several years. The most impressive results are obtained when operating in open hole, carbonated reservoirs or holes after lowering effect of hydraulic fracturing

Preliminary studies show that due to the selectivity of the Plasma Pulse Treatment on the producing formation and an increase in the permeability, the technology has application prospects on shale oil and gas fields, characterized by high segmentation of the formation and low permeability of reservoir.

References

-

Buntzen R., 1965. Studies of metal-water reactions by the exploding wire technique. Electric explosion of conductors. Moscow: Mir. pp. 225-238.

-

Chellapan S.K., Al Enezi F., et al., 2015. First application of plasma technology in KOC to improve well’s productivity. SPE Kuwait Oil & Gas Show and Conference 2015. SPE-175264-MS.

-

Nikolaevsky V.N., 1996. Geomechanics and fluid dynamics in application to gas and oil reservoirs problems. Мoscow: Nedra, 448 p.

-

Orlenko L.P., 2006. Physics of explosion and shock. Moscow: Fizmatlit.

-

Pashchenko A.F., Ageev P.G., 2015. Elastic waves and plasma – a new era of enhanced oil recovery. Proceedings of ICNAAM-2105. AIP Publishing, Vol. 1738, pp. 480053.

-

Tarnovsky E.I., 2009. Technology and techniques to increase components recovery from formations. Tomsk: TPU.

- Экологическая чистота, работает в естественных геологических условиях скважин без добавок реагентов;

- Плазменно-импульсное воздействие (ПИВ) используется при любой обводненности;

- Улучшает проницаемость прискважинной зоны добывающих и нагнетательных скважин, и продуктивных пластов в целом;

- Значительно увеличивает дебит нефти на скважинах эксплуатируемых на месторождениях поздней стадии разработки;

- Кратно увеличивает приемистость нагнетательных скважин вне зависимости от их предыдущего назначения;

- Воздействует на соседние с обрабатываемой скважины, которые откликаются положительным дебитом;

- Технология дает положительные результаты на месторождениях в коллекторах любой геологической сложности;

- Безопасна в эксплуатации;

- Сокращает период освоения новой скважины и срок вывода ее на режим эксплуатации.

| Главная | Услуги | О компании | Проекты | Технология | Контакты | Правовая информация | Карта сайта | О проекте | |

| тел: +7 (495) 225 62 40 / e-mail: info@novas-energy.ru |